In the complex landscape of industrial operations, the integration of reliable machinery with advanced control systems is key to enhancing efficiency and productivity. Weil Pumps and Hubbell Industrial Controls represent two cornerstone technologies in the modern industrial sector, each playing a pivotal role in optimizing processes and ensuring seamless operations.

The Role of Weil Pumps in Industrial Applications

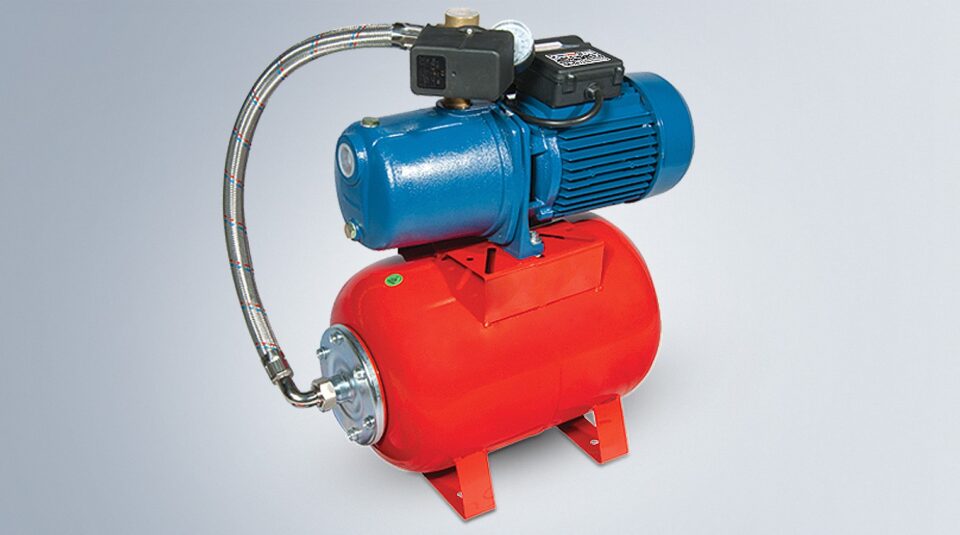

Weil Pumps are renowned for their robust construction and reliable performance, making them an ideal choice for demanding industrial environments. These pumps are designed to handle a wide range of fluids, from water to aggressive chemicals, ensuring efficient flow management in various processes.

Key Features:

- Durability: Constructed to withstand tough industrial conditions without degradation.

- Versatility: Suitable for multiple applications including wastewater management, chemical processing, and boiler feed operations.

- Energy Efficiency: Engineered to operate with minimal energy consumption, reducing overall operational costs.

Operational Applications:

- Manufacturing Facilities: Used in the production lines where precise fluid handling is crucial.

- Environmental Systems: Essential for managing waste and runoff in compliance with environmental regulations.

- Cooling Systems: Play a vital role in maintaining the temperature regulation within industrial plants.

For industry professionals looking for high-quality Weil pumps, Midwest Supply offers a diverse selection to meet various operational demands.

Hubbell Industrial Controls: Precision and Reliability

Hubbell Industrial Controls are synonymous with precision and reliability, providing the necessary control mechanisms to enhance the functionality of industrial equipment like Weil Pumps. These controls are designed to maximize efficiency and safety in industrial settings.

Key Features:

- Advanced Technology: Incorporates the latest advancements in control technology to ensure high accuracy and responsiveness.

- Safety Features: Equipped with numerous safety protocols to prevent accidents and ensure the protection of both machinery and personnel.

- Integration Capability: Easily integrated with existing systems, allowing for seamless upgrades and enhancements.

Applications in Industrial Settings:

- Process Automation: Hubbell controls are crucial for automating processes, reducing the need for manual intervention and increasing operational efficiency.

- System Monitoring: Provides real-time data on system performance, aiding in preventive maintenance and troubleshooting.

- Energy Management: Optimizes energy use, crucial for reducing operational costs in energy-intensive environments.

For accessing a wide range of control solutions, the Hubbell Industrial Controls section at Midwest Supply is an excellent resource for industrial operators.

Integrating Weil Pumps with Hubbell Controls

The integration of Weil Pumps with Hubbell Industrial Controls can lead to significant enhancements in system efficiency and reliability. This combination allows for a more cohesive and synchronized operation, where pumps are optimally controlled to match the demands of the system without overuse or energy wastage.

Benefits of Integration:

- Enhanced Operational Efficiency: Controls ensure that pumps operate only when needed and at optimal levels, reducing wear and energy usage.

- Improved System Lifespan: Proper control can reduce the mechanical strain on pumps, extending their operational lifespan.

- Increased Automation: Allows facilities to automate more processes, reducing the potential for human error and freeing up human resources for more critical tasks.

The Impact on Industrial Efficiency

The synergy between Weil Pumps and Hubbell Industrial Controls not only enhances the individual performance of the systems but also contributes to a broader impact on industrial efficiency. This integration leads to:

- Reduced operational costs through improved energy efficiency.

- Lower maintenance costs due to enhanced durability and proactive system monitoring.

- Greater overall system reliability, ensuring continuous production without downtime.

Industries looking to upgrade or enhance their systems would do well to consider integrating these technologies. With solutions available from trusted suppliers like Midwest Supply, it is easier than ever to access high-quality equipment that can bring about tangible improvements in industrial efficiency. This strategic integration represents a forward-thinking approach to industrial operations, ensuring that facilities remain competitive and sustainable in an increasingly complex operational landscape.